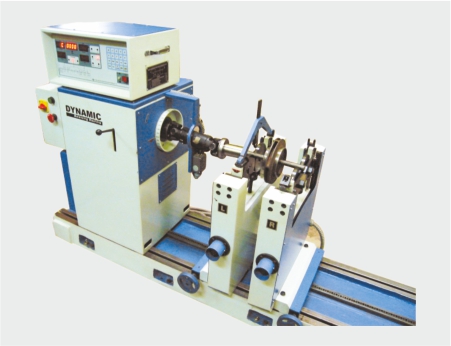

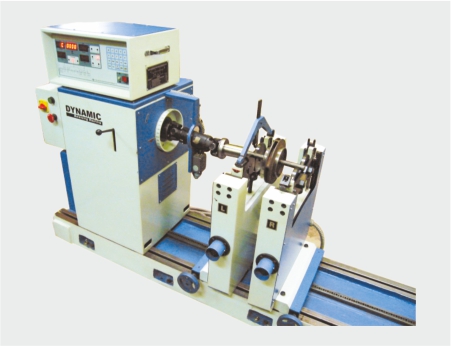

Pump Support System

Pump Support System

Features

- Easy to understand, menu driven 'Windows' based software.

- Unlimited data storage (Limited by PC Hard Disk capacity)

- Extensive RDBMS type database support.

- Detailed test report/Certificate print format.

- Built-in balancing tolerance presetting for both balancing Planes.

- Built-in tolerance calculator as per ISO

- Built-in Auto Ranging and Auto Tracking Filter

- Built-in special function to separate couple & static unbalance.

- Simultaneous display of results for both balancing planes.

| Models |

Unit |

IPHB-10 |

IPHB-30 |

IPHB-50 |

IPHB-100 |

IPHB-300 |

IPHB-650 |

IPHB-1T |

IPHB-2T |

IPHB-3T |

IPHB-7T |

IPHB-10T |

IPHB-20T |

| Weight of the job |

Kg |

0.5-10 |

1-30 |

2-50 |

3-10 |

10-300 |

6.5-650 |

10-1000 |

20-2000 |

30-3000 |

70-7000 |

100-10000 |

200-20000 |

| Max Diameter of job |

mm |

500 |

500 |

500 |

1000 |

1000 |

1200 |

1600 |

1800 |

2000 |

2400 |

2400 |

3000 |

| Maximum distance measured from coupling end to extreme bearing center |

mm |

500 |

500 |

1200 |

1400 |

1400 |

1400 |

1650 |

1650 |

2400 |

3300 |

3300 |

5000 |

| Minimum distance between bearing |

mm |

50 |

75 |

75 |

90 |

110 |

200 |

350 |

350 |

500 |

560 |

560 |

660 |

| Journal Diameter |

mm |

5-50 |

5-50 |

5-50 |

15-80 |

20-120 |

20-120 |

25-140 |

30-160 |

35-200 |

55-300 |

55-300 |

70-350 |

| Balancing Speed of Machine |

RPM |

1200 |

700 |

700 |

600 |

500 |

350-700 |

300-600 |

250-500 |

250-500 |

200-400 |

200-400 |

180-360 |

| Drive Motor |

HP |

0.33 |

0.75 |

0.75 |

1.5 |

3 |

5 |

7.5 |

10 |

20 |

30 |

40 |

60 |

| Acceleration Capability (Gd²N²) |

Kgm²n² |

0.29x106 |

0.37x106 |

0.37x106 |

0.88x106 |

3.9x106 |

8.5x106 |

14.12x106 |

44x106 |

88x106 |

168x106 |

216x106 |

400x106 |

| Minimum unbalance mass read |

gm |

0.01 |

0.1 |

0.1 |

0.1 |

0.2 |

0.1 |

0.2 |

0.2 |

4 |

1 |

1 |

2 |

| Maximum unbalance mass measured |

gm.mm |

104/sup> |

3x104 |

5x104 |

105 |

3x105 |

6.5x105 |

105 |

2x106 |

3x106 |

7.0x106 |

107 |

2x107 |

| Minimum unbalance measured |

gm.mm |

0.5 |

1.25 |

2.5 |

5 |

15 |

5 |

10 |

10 |

20 |

60 |

60 |

160 |

| Minimum achivable unbalance (for Minimum weight of rotor) |

Microns or gm.mm.kg |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |